UK Researchers Seek to Develop Antiviral Membrane Mask

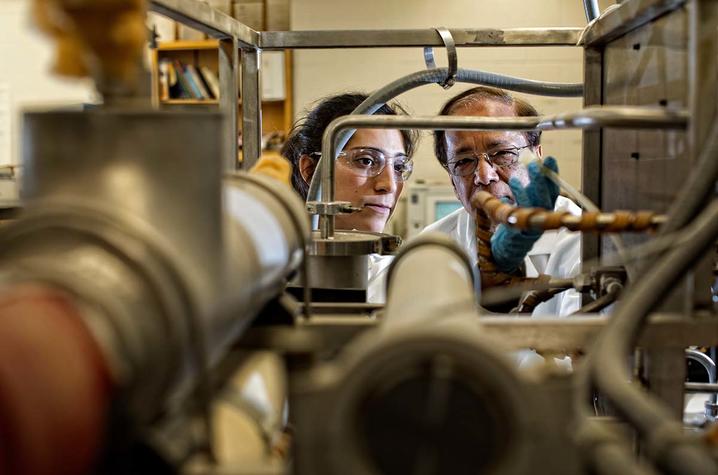

Dibakar Bhattacharyya has been a fixture in the University of Kentucky’s College of Engineering for more than 50 years and is renowned for his research, which focuses on incorporating life sciences materials with synthetic membranes for filtering and producing clean water.

Today, the director of UK’s Center of Membrane Sciences, known to friends and colleagues as “DB,” is contributing his decades of membrane expertise to help address the spread of the novel coronavirus. He has the concept and the means to develop a medical face mask that would capture and deactivate the COVID-19 virus on contact.

“We have the capability to create a membrane that would not only effectively filter out the novel coronavirus like the N95 mask does, but deactivate the virus completely,” said DB. “This innovation would further slow and even prevent the virus from spreading. It would also have future applications to protect against a number of human pathogenic viruses.”

DB’s idea is to create a membrane mask with a more porous and spongy structure that will include charged domain and enzymes, which would capture and effectively deactivate the virus.

“The novel coronavirus is covered in club-shaped “s-protein” spikes, which give it its crownlike, or coronal, appearance. The protein spikes are also what allows the virus to enter host cells once in the body. This new membrane will include proteolytic enzymes that will attach to the protein spikes of the coronavirus and separate them, killing the virus,” said DB.

The new membrane will build upon the center’s National Institute of Environmental Health Sciences (NIEHS) and National Science Foundation (NSF) funded activities, which have developed various functionalized membranes for environmental remediation. In contrast to passive membranes, functionalized membranes provide additional benefits by interacting with undesired particles like viruses through selective binding or deactivation.

To create and test the membrane, DB plans to collaborate with researchers across campus including Thomas Dziubla, Isabel Escobar and Zach Hilt from the College of Engineering, Allan Butterfield in the College of Arts and Sciences, and Thomas Chambers with the College of Agriculture, Food and Environment.

He and his co-researchers plan to gather preliminary data for the proposal and submit to the National Institutes of Health or NSF, which has recently called for immediate proposals that have potential to address the spread of the virus.

He says the process would take around six months to create the finished and tested product. The work will then be facilitated through existing collaboration with a large-scale membrane manufacturer.

DB says this type of collaboration across disciplines is a testament to the innovative and collaborative spirit of the university, as well as its service-centered mission.

“At the University of Kentucky, we have great resources at our fingertips and many opportunities to engage in cutting-edge research across disciplines,” DB said. “Our researchers work together and lend their expertise to solve challenges for the greater good of humanity, not only at a time like this, but every day.”

More from this series Research Support

Credits

Elizabeth Chapin (Research Communications)