CAER Project Seeks to Create More Environmentally Friendly, Stronger Cement

Cement production is the world’s second largest source of carbon dioxide emissions. Reducing CO2 in the built environment is one of the most challenging engineering questions of our time, and scientists at the University of Kentucky Center for Applied Energy Research (CAER) are at the forefront of innovation and discovery in this area.

CAER has received a two-year, $1.3 million grant to develop extremely durable belite-based cement — an alternative to ordinary Portland cement — that is low-energy consuming and low-carbon dioxide releasing.

The project, titled “Belite Cement, and Concretes; Novel Low-Energy Approaches to Making Concrete Extremely Durable,” is funded by the U.S. Department of Energy Advanced Research Projects Agency–Energy (ARPA-E).

“If you are seeking to reduce carbon dioxide in the built environment, there are two approaches that make sense,” said Bob Jewell, principal investigator for the project and research program manager at CAER. “The first is to ‘build to last.’ Increasing the life of major structures effectively reduces their carbon footprint. The second approach is to use materials and methods that produce less carbon emissions.

“Our project is seeking to check both of these boxes. The material would use less energy, release less CO2, and excel in performance and durability over time.”

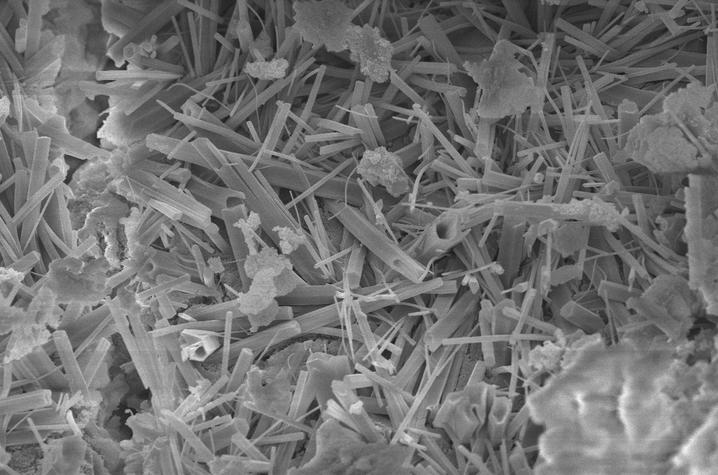

Belite-rich Portland cement is fabricated with less limestone (CaCO3) at lower temperatures, resulting in fewer carbon emissions. Unfortunately, belite cements build strength at a slower rate, a drawback in construction. This particular grant seeks to develop a durable, low-carbon belite-rich cement that also performs comparably to conventional Portland cement.

Partnering with CAER on this project are Designs by Natural Processes Inc., Sandia National Laboratory and Titan America LLC.

More from this series Research Priorities - Energy

Credits

Dave Melanson (Center for Applied Energy Research)